As consumer demands grow, so do the difficulties for the entire supply chain, which must be able to reorganise itself to ensure ever shorter delivery times and greater levels of customisation of deliveries.

Suffice it to say that according to a recent SendCloud survey, 86% of Italian e-shoppers believe that shipping speed has a considerable influence on their choice of eCommerce, while 42% of users expect delivery within 24 to 48 hours.

In recent years, therefore, we have witnessed great changes, both from the point of view of consumption habits – also due to the Covid-19 pandemic – and from the point of view of production, due to globalisation and digitalisation.

Supply chains have thus grown to become complex international structures composed of elements located in different countries. Consequently, the tools to manage them have also had to evolve.

What is meant by decoupling

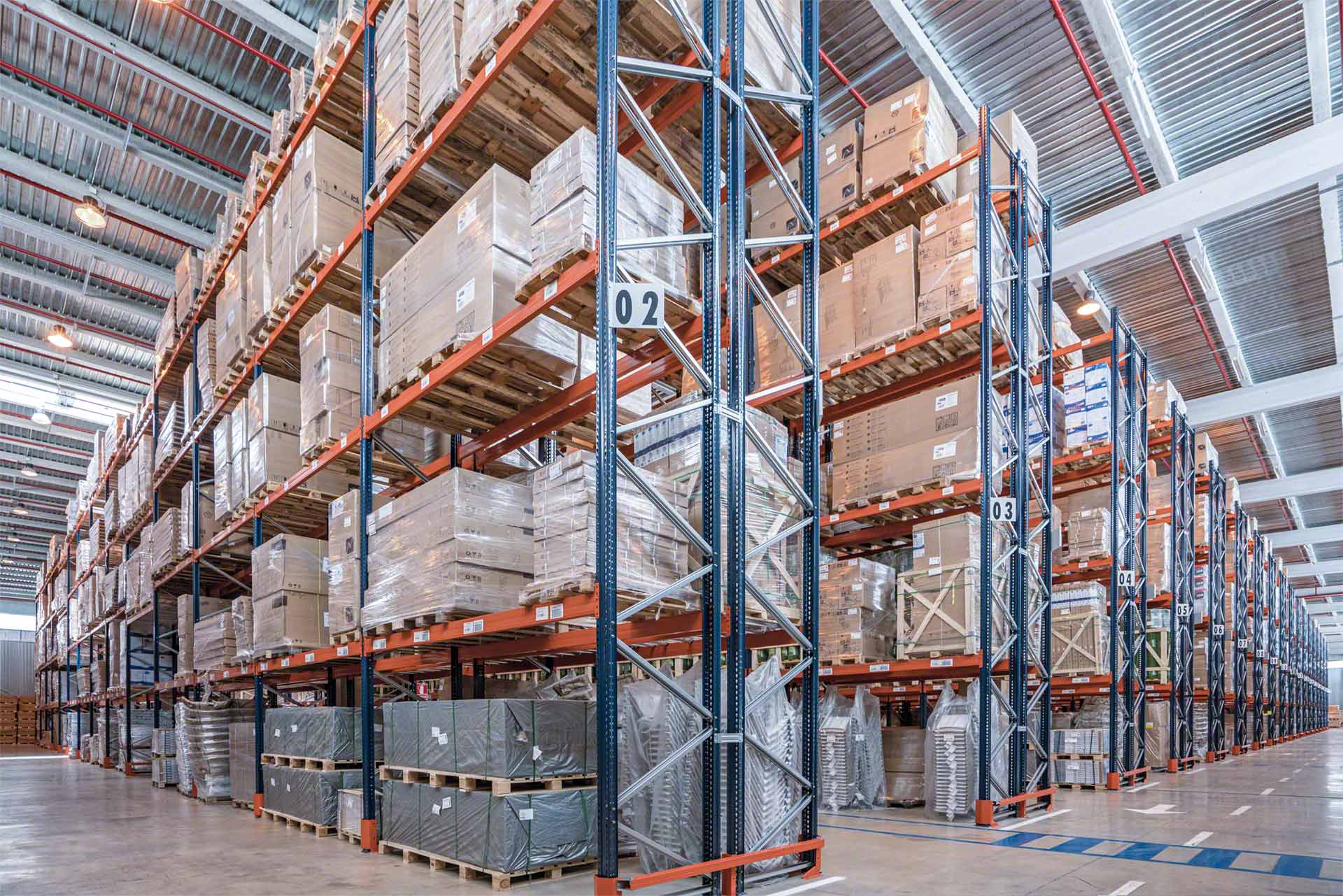

One of these tools is decoupling or, literally, ‘decoupling’. That is a strategy that allows intermediate inventories of materials, components and finished products to be placed throughout the supply chain so that possible fluctuations caused by reordering of materials do not restrict production, thereby reducing the so-called ‘whiplash effect‘, i.e. an amplification of demand that results in an exponential acceleration of orders and stock supply requirements.

These intermediate inventories are referred to as buffers, i.e. quantities of material or semi-finished products that are expected to be consumed in a given period of time and are used to produce new material and ensure a safety margin. Accurately positioned decoupling buffers therefore ensure the availability of materials by avoiding whiplash effect and stock breaks.

How decoupling works

Decoupling, therefore, is a technique that creates independence between the supply of material and its use. It is a key principle by which it is possible to ensure responsiveness to demand, manage supply priorities in an organised manner and stabilise flow at weak points.

The introduction of decoupling points means that the response time, the lead time, is also divided into the so-called decoupled lead time, thanks to which planning errors can be reduced and flexibility increased.

Decoupling points also enable planners and procurers to know at any time what the situation is in their supply chain regarding the materials they will need to meet demand in the short and medium term. This enables them to order materials and components on time, thus improving On Time Delivery and the level of the entire service. Urban hubs of this type can thus be put at the service of transporters and logistics operators. How?

A service to support transporters and logistics operators

Last-mile logistics establishments – as also pointed out in a recent World Capital study – in addition to meeting supply needs, must also be able to rely on an efficient system of infrastructure and connection networks. The correct location of a last mile facility is therefore of paramount importance to reduce logistics costs while making the service more efficient and optimised.

According to a study by the Chalmers University of Technology in Gothenburg, Sweden, moreover, since last mile transport, as we have also seen here, is one of the most polluting parts of the entire logistics chain and causes a great deal of energy consumption, this last resource could be saved by bringing goods to collection points – urban hubs, in fact – closer to the point of consumption.

The GEL Proximity software provides logistics operators and transporters with a variety of last-mile solutions, including the decoupling of goods to their last-mile delivery at thousands of Pick-up Points. In GEL Proximity’s urban hubs located throughout the country, last-mile shipments can be received, collected and sorted with the operational support of Partners.

If you are interested in our service or need more information, you can contact us.